Namur Citadel’s Gondola

Voreppe, Saturday, 8 May 2021. Maxime Prévot, Mayor of Namur, Belgium, Christian Bouvier, Vice President of the Supervisory Board of POMA, Jean-Yes Remy, CEO of Labellemontagne and Philippe Beaujean, Director of Franki today unveiled a new gondola in Namur.

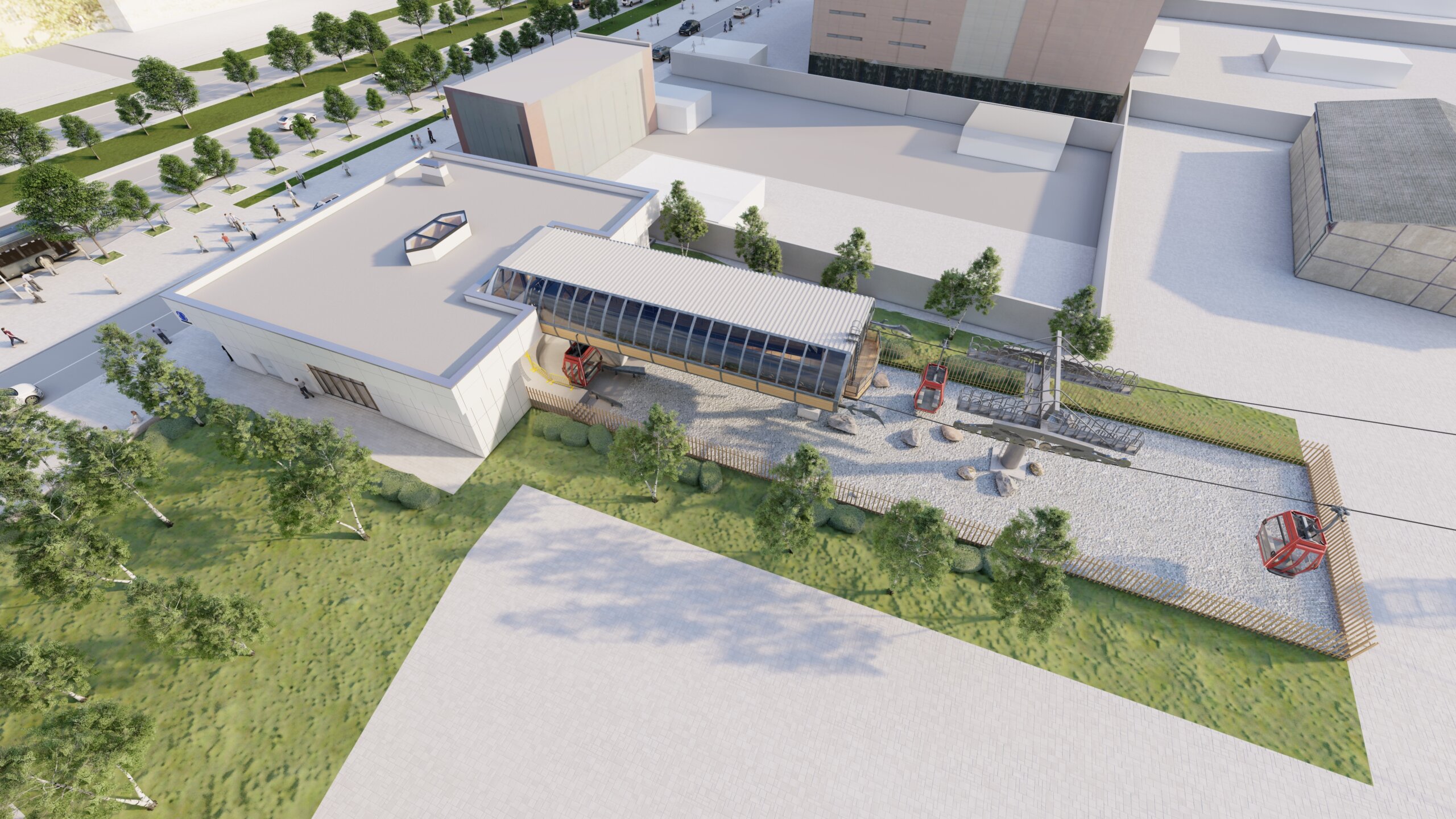

The Namur gondola connects the historic city centre to the listed Citadel of Namur. This new project, undertaken by POMA and its partners Labellemontagne and Franki, now offers a new perspective on the Belgian city, enhancing its appeal to tourists. This is POMA’s first Belgium-based project and the first European tourism concession it has put its name to.

TO ITS HISTORY

Namur residents will remember the first cable car installed in 1956 that took them to the top of the citadel up until 1997. Namur'snew gondola takes a different route today, rising over the Sambre and linking the city centre from Maurice Servais Square to the upper station on the Citadel's Esplanade, a stone's throw from the Digital Pavilion, a legacy from the Milan World Expo.

The gondola is both a useful link and an environmental plus, offering an alternative traffic route in the Walloon capital.

OF TRADITION AND MODERNITY

Designed to blend in with the urban landscape, the gondola's contemporary architecture respects this unique site. The two stations, built from Namur's typical red brick, blend discreetly with the surroundings. The technical parts of the gondola are well camouflaged and the ingenious design of the transparent glass surfaces allows perfect integration with the surrounding buildings. Careful attention has been paid to the installation of the towers. Of the four on the line, only one is obviously visible, the others merging discretely with the Terra Nova trees.

The designers were also careful to minimise the noise levels of the drive station. To reduce energy usage, the Diamond cabins are equipped with solar panels that power interior and exterior LED lighting.

« Choosing to work with POMA, Labellemontagne and Franki has allowed us to surround ourselves with experts. It was with full confidence that we entrusted them with this project. I strongly believe that the gondola will be of huge benefit to tourism and mobility. A real feather in the city’s cap! »

Mayor of Namur

MULTIFUNCTIONAL TOURIST GONDOLA

The two trains of the three Diamond cabins will run in line at 6 metres per second, slowing down at the stations to allow pedestrians, pushchair users, wheelchair users and cyclists to get in and out safely and comfortably. In terms of design and on-board comfort, large windows provide an enjoyable, unrestricted view of the city. The journey will be a unique experience, giving passengers a new perspective as they are silently transported upwards over the city.

The Namur gondola will also enable residents of the citadel’s neighbourhoods to reach the city centre in four minutes. There will be extended timetables to benefit daily commuters.

The three partner companies in this project – POMA, Labellemontagne and Franki – have formed a consortium, the Société Anonyme du Téléphérique de la Citadelle de Namur, which will operate the gondola over the next thirty years.

+ NEWS

Téléphérique Angelo

Le téléphérique Angelo, inauguré à Ajaccio en Corse le 18 octobre 2025, renforce l’offre de transport urbain de la ville. Il relie plusieurs quartiers en 12 minutes de manière écologique et en assurant l’intermodalité avec les autres modes de transports. Conçu et exploité par POMA, il améliore la mobilité, réduit la congestion et symbolise un lien durable entre les habitants et les territoires.

Learn moreMOUNTAIN PLANET ENG

The Mountain Planet 2024 exhibition will be held from April 16 to 18 at Alpexpo, Grenoble. In 2024, the commitment of POMA, a world reference in cable transportation, is reflected in a new range of products and services that are increasingly efficient and eco-responsible, for a lower environmental impact.

Learn moreSantiago de los Caballeros inaugurates its firts aerial tramway

A second urban cable car line has been inaugurated in Santo Domingo. The 4-kilometre cable car line connects the city centre and the western outskirts of the capital with the city’s transport network. For the first time in the world, a cable car line is operating at a speed of 7m/s in an urban environment !

Learn moreIn Santo Domingo capital, inauguration of the POMA’s 2nd urban cable car line

A second urban cable car line has been inaugurated in Santo Domingo. The 4-kilometre cable car line connects the city centre and the western outskirts of the capital with the city’s transport network. For the first time in the world, a cable car line is operating at a speed of 7m/s in an urban environment !

Learn more

The work site is in full swing

In Saint-Denis de la Réunion, the outlines of the urban cable car take shape. Within one year, the stations and the lines have almost been completed! The commissioning should be by the end of 2021.

OF LA REUNION GONDOLA LIFT

The work site keeps moving forward with the achievement of several crucial steps. By the end of 2020, the municipal association CINOR (Communauté intercommunale Du Nord de la Réunion) and the FILAO-Group (Atelier Architectes, POMA and Egis) had completed the earthworks, the towers foundations' concrete work and a part of the assembly. To date, 42 towers have been installed out of the 42 planned and the 5 stations along the ride have been delivered.

Currently, the teams finalize the adjustments on the stations. As for the vehicles, in April, 46 cabins have been delivered on site and are now being assembled in the garage for their upcoming installation on the cable.

On the “Téléférik” site

INTERVIEW

« We have crossed a big milestone in 2020 which was mainly focused on the infrastructures »

SBTPC/SOGEA Reunion Works manager

OF THE PROJECT

At the beginning of June, assisted by a drone, the teams will unwind the first cable between the towers. An unprecedented operation in our profession that our COMAG technicians master perfectly. Indeed, they have recently carried out the same intervention in the future Toulouse urban cable car project.

After the splicing that will complete the unwinding process, cabins can finally be hung on the cable, thereby giving to the locals an accurate idea of the final appearance of the future urban mobility system. Besides the system's technical and safety adjustments, the coming months will mainly be focused on the development of the areas around the stations. Constructions of park-and-ride facilities at Bancoul and Bois de Nèfles stations are planned as well as pedestrian walkways and the implementation of safety equipments in and around the stations. Le Chaudron bus station will also be redeveloped to fit the new adjustments. Thus, the commissioning of Saint-Denis de La Reunion gondola lift, planned for the second half of 2021, will offer a sustainable and multimodal transport solution to its users.

1ST INDIAN OCEAN’S GONDOLA LIFT

Saint-Denis’ 2.68 km-long gondola lift will link Chaudron to Bois de Nèfles districts via Moufia in only 14 minutes.

The “Téléférik” project comes from the local population strong desire, in agreement with the elected representatives, to establish a compact, fast and sustainable means of transport in the city. This very first urban ropeway will make the traffic on the island flows more freely and it will also enables to create an economic dynamic within the districts with new living areas and local shops such as for Chaudron and Bois de Nèfles (right by the new high school).

FIND OUT MORE ABOUT THE PROJECT IN VIDEO

+ NEWS

Téléphérique Angelo

Le téléphérique Angelo, inauguré à Ajaccio en Corse le 18 octobre 2025, renforce l’offre de transport urbain de la ville. Il relie plusieurs quartiers en 12 minutes de manière écologique et en assurant l’intermodalité avec les autres modes de transports. Conçu et exploité par POMA, il améliore la mobilité, réduit la congestion et symbolise un lien durable entre les habitants et les territoires.

Learn moreMOUNTAIN PLANET ENG

The Mountain Planet 2024 exhibition will be held from April 16 to 18 at Alpexpo, Grenoble. In 2024, the commitment of POMA, a world reference in cable transportation, is reflected in a new range of products and services that are increasingly efficient and eco-responsible, for a lower environmental impact.

Learn moreEUROPEAN MOBILITY EXPO

Le Salon Européen de la mobilité, le EuMo Expo 2022 se tiendra du 7 au 9 juin à Paris-Expo Porte de Versailles, Paris. Tous les deux ans, le EuMo Expo, rassemble plus de 250 exposants français et internationaux, tous acteurs du transport public et de la mobilité durable.

Learn more12ème COLLOQUE NATIONAL EOLIEN

The National Wind Energy Conference will be held for the 12th time this year. From 12 to 13 October at Parc Floral de Paris, various wind energy experts, scientists, associations and companies come together to talk about new and already realized projects in the sense of the energy transition in France.,

Learn more

the “Ain Dubai” capsules are installed

Barely 2 years after the launch of the project, POMA has finalized the installation of 48 non-standard capsules on Bluewaters Island, in Dubai (United Arab Emirates).

the POMA Group’s DNA

At the beginning of 2019, Hyundai Engineering & Construction awarded leading ropeway transportation company, POMA, the EPCI contract* to provide the 48 capsules for the world's newest and biggest observation wheel “Ain Dubai”.

POMA has been designing and building largescale projects in the Entertainment sector for many years. A project of this scale calls for the highest levels of technological expertise, combined with unparalleled know-how.

Forty-eight outsized and completely original capsules, each able to accommodate up to 40 people, were designed, built and installed in a record time of less than 24 months.

A world record!

Capsules 250 meters high

Located 500 metres from the coasts of JBR beach and Dubai Marina, the observation wheel “Ain Dubai” (“the Dubai eye”) will offer its guests a panoramic view of the city and the bay, while setting the new height world record of 250m (twice the size of the London Eye).

the preferred partner

Innovating and designing exactly the right engineering solutions while guaranteeing safety, efficiency and cost-effectiveness, is part of POMA's DNA.

The Group has, in particular, fine-tuned its engineering expertise and its unique technical prowess in the sector through involvement in the delivery of numerous special projects:

- Big observation wheels in London with the London Eye and in Las Vegas with the High Roller

- Other complex projects, in particular the incredible British Airways i360 observation tower in Brighton…

- Regular provision of capsules for smaller observation wheels: Baku, Chicago, Hong Kong…

for fast track projects

As well as mastering the technology to successfully complete complex projects, POMA benefits from an agile organization enabling close joint-construction with the customer or managing the Group's multicultural and multi-expert teams and its subcontractors, who, for the “Ain Dubai” project, were coordinated from France but based in seven countries on four different continents.

The design and manufacture of the 48 capsules for “Ain Dubai” was a fast track project, carried out in under two years. This project clearly demonstrates the French Group's ability to export its services, tackle innovative projects and handle tight deadlines.

Confronted by the uncertainty of the health crisis, POMA's teams had to adapt almost continuously to deliver the 48 capsules and limit the impact on the construction site to a minimum.

Download the Press Release

+ news

Téléphérique Angelo

Le téléphérique Angelo, inauguré à Ajaccio en Corse le 18 octobre 2025, renforce l’offre de transport urbain de la ville. Il relie plusieurs quartiers en 12 minutes de manière écologique et en assurant l’intermodalité avec les autres modes de transports. Conçu et exploité par POMA, il améliore la mobilité, réduit la congestion et symbolise un lien durable entre les habitants et les territoires.

Learn moreMOUNTAIN PLANET ENG

The Mountain Planet 2024 exhibition will be held from April 16 to 18 at Alpexpo, Grenoble. In 2024, the commitment of POMA, a world reference in cable transportation, is reflected in a new range of products and services that are increasingly efficient and eco-responsible, for a lower environmental impact.

Learn moreSantiago de los Caballeros inaugurates its firts aerial tramway

A second urban cable car line has been inaugurated in Santo Domingo. The 4-kilometre cable car line connects the city centre and the western outskirts of the capital with the city’s transport network. For the first time in the world, a cable car line is operating at a speed of 7m/s in an urban environment !

Learn moreIn Santo Domingo capital, inauguration of the POMA’s 2nd urban cable car line

A second urban cable car line has been inaugurated in Santo Domingo. The 4-kilometre cable car line connects the city centre and the western outskirts of the capital with the city’s transport network. For the first time in the world, a cable car line is operating at a speed of 7m/s in an urban environment !

Learn more

POMA will implement the first urban ropeways in Ulaanbaatar

POMA is in charge of a cable transport project for the city of Ulaanbaatar, capital of Mongolia. The project is financed by the Directorate General of the Treasury with the aim of developing urban mobility.

substantial urban obstacles

Mongolia's political and economic capital Ulaanbaatar has experienced rapid population growth due to an influx of nomadic people arriving from the steppe since the early 1990s.

This has resulted in Ulaanbaatar having nearly 1.5 million inhabitants, accounting for nearly half of the country's population, compared with 580,000 in 1990. The transition to a market economy since the 1990s and a succession of harsh winters precipitated the exodus of these low-income households to the edges of Ulaanbaatar.

These suburbs have become commonly known as “Ger districts” due to the multitude of traditional yurts to be found there, known as gers in Mongolia.

the ideal transport solution

In a city featuring major obstacles (notably, the Tuul-Gol river and the Trans-Mongolian Railway), and with a relatively undeveloped transport network, this urban cable car system emerges as the most appropriate solution. With its silent, all-electric and low energy operation, ropeway transport is today an acknowledged and sustainable urban transport mode, capable of addressing specific problems of cities and with the added benefit of being quicker to implement than other forms of transport infrastructure.

The French Directorate General of the Treasury (DG Trésor), which supports French firms in the delivery of structurally transformational, eco-friendly and sustainable projects, therefore decided to finance this urban mobility project developed by the company POMA with the support of EGIS, for the benefit of Ulaanbaatar city council.

The line, located to the west of the city, is 4.2 km long. It has two stations and 98 cabins.

It connects a historic, densely populated neighbourhood with a bus station and busy shopping centres to a rapidly developing area where the new town hall is located, along the main road leading to the airport.

This project addresses a crucial issue: despite their importance, these two areas are currently very poorly served. There is no structured public transport system, apart from a few bus routes, and traffic is heavily congested, with no direct road link between these neighbourhoods. The line is therefore part of a strategy to open up the area and improve mobility, in line with ongoing development programmes, in particular the redevelopment and densification plan financed by the Asian Development Bank (ADB).

project

Entirely managed by POMA, which is responsible for the design and construction of public and technical buildings with the support of local contractors, this turnkey project demonstrates our comprehensive expertise and our ability to carry out complex projects in demanding environments. As the infrastructure takes shape, local pride grows: a new form of mobility is emerging in Mongolia.

Cable transport in Ulaanbaator

They talk about it

Our unique know-how will be harnessed to deliver this transformational project for the city of Ulaanbaatar. Our cable transport solution is a perfect fit with the principle of reducing environmental impact and substantially enhancing urban mobility in Ulaanbaatar and its outskirts, in particular the connection of the new district of Bayankhoshuu with the city centre. This is a project that makes sense for the development of this capital city and its suburbs, in the same way as has previously been achieved in Latin America and with our projects in France, in Toulouse and Ajaccio. For this first ropeway line in the country, POMA and partners joined forces to deliver a turnkey project, made in France.

President of POMA

+ infos

Téléphérique Angelo

Le téléphérique Angelo, inauguré à Ajaccio en Corse le 18 octobre 2025, renforce l’offre de transport urbain de la ville. Il relie plusieurs quartiers en 12 minutes de manière écologique et en assurant l’intermodalité avec les autres modes de transports. Conçu et exploité par POMA, il améliore la mobilité, réduit la congestion et symbolise un lien durable entre les habitants et les territoires.

Learn moreMOUNTAIN PLANET ENG

The Mountain Planet 2024 exhibition will be held from April 16 to 18 at Alpexpo, Grenoble. In 2024, the commitment of POMA, a world reference in cable transportation, is reflected in a new range of products and services that are increasingly efficient and eco-responsible, for a lower environmental impact.

Learn moreEUROPEAN MOBILITY EXPO

Le Salon Européen de la mobilité, le EuMo Expo 2022 se tiendra du 7 au 9 juin à Paris-Expo Porte de Versailles, Paris. Tous les deux ans, le EuMo Expo, rassemble plus de 250 exposants français et internationaux, tous acteurs du transport public et de la mobilité durable.

Learn more12ème COLLOQUE NATIONAL EOLIEN

The National Wind Energy Conference will be held for the 12th time this year. From 12 to 13 October at Parc Floral de Paris, various wind energy experts, scientists, associations and companies come together to talk about new and already realized projects in the sense of the energy transition in France.,

Learn more

the “Ain Dubai” capsules are installed

Barely 2 years after the launch of the project, POMA has finalized the installation of 48 non-standard capsules on Bluewaters Island, in Dubai (United Arab Emirates).

the POMA Group’s DNA

At the beginning of 2019, Hyundai Engineering & Construction awarded leading ropeway transportation company, POMA, the EPCI contract* to provide the 48 capsules for the world's newest and biggest observation wheel “Ain Dubai”.

POMA has been designing and building largescale projects in the Entertainment sector for many years. A project of this scale calls for the highest levels of technological expertise, combined with unparalleled know-how.

Forty-eight outsized and completely original capsules, each able to accommodate up to 40 people, were designed, built and installed in a record time of less than 24 months.

In 2017, the Namur municipal college awarded the construction of this gondola lift to the POMA, Franki and Labellemontagne consortium. POMA is responsible for the design and construction of the cable car and will support Labellemontagne for operation and maintenance.

Technologically, this “cable car” is a pulsed gondola lift, with two trains of three cabins each accomodationg six passengers, which ascends in 3 minutes. This technology is particularly well suited to tourist transport with compact stations and guaranteeing optimal acoustic comfort for both users and residents.

Helicopter transport in Namur

technical specifications

of the Citadel Gondola lift

- Length : 352 m

- Difference in elevation : 102 m

- Number of stations : 2

- Speed : 6 m/s

- Capacity : 290 – 408 pph

- Number of carriers : 2 trains x 3 cabins

- Number of vehicules : 6

- Number of passenger per vehicules : 6

- Total travel time : 3’30 min

+ news

Téléphérique Angelo

Le téléphérique Angelo, inauguré à Ajaccio en Corse le 18 octobre 2025, renforce l’offre de transport urbain de la ville. Il relie plusieurs quartiers en 12 minutes de manière écologique et en assurant l’intermodalité avec les autres modes de transports. Conçu et exploité par POMA, il améliore la mobilité, réduit la congestion et symbolise un lien durable entre les habitants et les territoires.

Learn morePOMA and TISSEO inaugurate the longest urban cable car in Europe in Toulouse

The longest urban cable car in France and Europe, Téleo, has been inaugurated in Toulouse. Fast and eco-responsible, the aerial line covers 3 kilometers in about ten minutes and serves one of the city’s major activity areas, perfectly interconnected with its transportation network.

Learn morePOMA and TISSEO unveil the cabin of Toulouse’s future urban aerial tramway

In Toulouse, on 28 May 2021, in the presence of mayor Jean-Luc Moudenc, Tisséo unveiled the cabin of Téléo, Toulouse’s future urban aerial tramway. Over the next few weeks, Sigma’s 34-seat Symphony cabin will be on display in the famous Place du Capitole.

Learn moreThe construction of la Reunion’s first urban cable car progresses

In Saint-Denis de la Réunion, the outlines of the urban cable car take shape. Within one year, the stations and the lines have almost been completed! The commissioning should be by the end of 2021.

Learn morePOMA will implement the 1st urban ropeways of Mongolia

POMA has been tasked with a cable transportation project for the city of Ulaanbaatar, the capital of Mongolia. POMA will implement the first urban ropeways in Ulaanbaatar.

Learn more

the “Ain Dubai” capsules are installed

Barely 2 years after the launch of the project, POMA has finalized the installation of 48 non-standard capsules on Bluewaters Island, in Dubai (United Arab Emirates).

2 days in pictures

Testimony

Vincent Vanneyre

This event was the perfect opportunity to get involved in a cause that I support, to meet one of my friends there and share his passion together with some other POMA co-workers.

The program lived up to the memories that I have, and which constantly gives me the desire to continue to invest myself: sharing moments of life and hint of happiness where everyone contributes in his own way.

An experience not to be missed under any circumstances, where people, disabilities and nationalities mingle indiscriminately!

Ingénieur maintenance, POMA

read +

MOUNTAIN PLANET ENG

The Mountain Planet 2024 exhibition will be held from April 16 to 18 at Alpexpo, Grenoble. In 2024, the commitment of POMA, a world reference in cable transportation, is reflected in a new range of products and services that are increasingly efficient and eco-responsible, for a lower environmental impact.

Learn moreEUROPEAN MOBILITY EXPO

Le Salon Européen de la mobilité, le EuMo Expo 2022 se tiendra du 7 au 9 juin à Paris-Expo Porte de Versailles, Paris. Tous les deux ans, le EuMo Expo, rassemble plus de 250 exposants français et internationaux, tous acteurs du transport public et de la mobilité durable.

Learn more12ème COLLOQUE NATIONAL EOLIEN

The National Wind Energy Conference will be held for the 12th time this year. From 12 to 13 October at Parc Floral de Paris, various wind energy experts, scientists, associations and companies come together to talk about new and already realized projects in the sense of the energy transition in France.,

Learn moreFabien Felli succeeds Jean Souchal to POMA Presidency

On June 28th 2022, Fabien Felli succeeds Jean Souchal to POMA Presidency

Learn more