SACMI

A subsidiary of the POMA Group since 1960, SACMI specialises in mechanical welding, machining, installation and assembly of mechanical sub-assemblies for ropeway transport systems. A know-how developed in the heart of the Alps and an industrial structure commensurate with the most ambitious projects.

POMA therefore relies on the expertise of its subsidiary to deal with very specific requests such as the development of tri-cable ropeways for China, observation wheel capsules or even onshore wind turbines for the activity of POMA Leitwind! Thanks to its strategic position, SACMI is also the Group’s main logistics hub from which all equipment travels around the world to become iconic “Made in France” projects.

the mechanical welding expert of the Poma Group

Mechanical welding of ropeway transport sub-assemblies

For more than 60 years, SACMI has been producing metal parts for ropeway transport structures. The industrial mastery of the manufacturing processes (sheet metal making, manual and robot welding) allows SACMI to adapt to different request and to remain flexible in terms of deadlines and costs, while complying with demanding quality standards (SACMI is notably EN 1090 EXC4 and ISO 9001 certified).

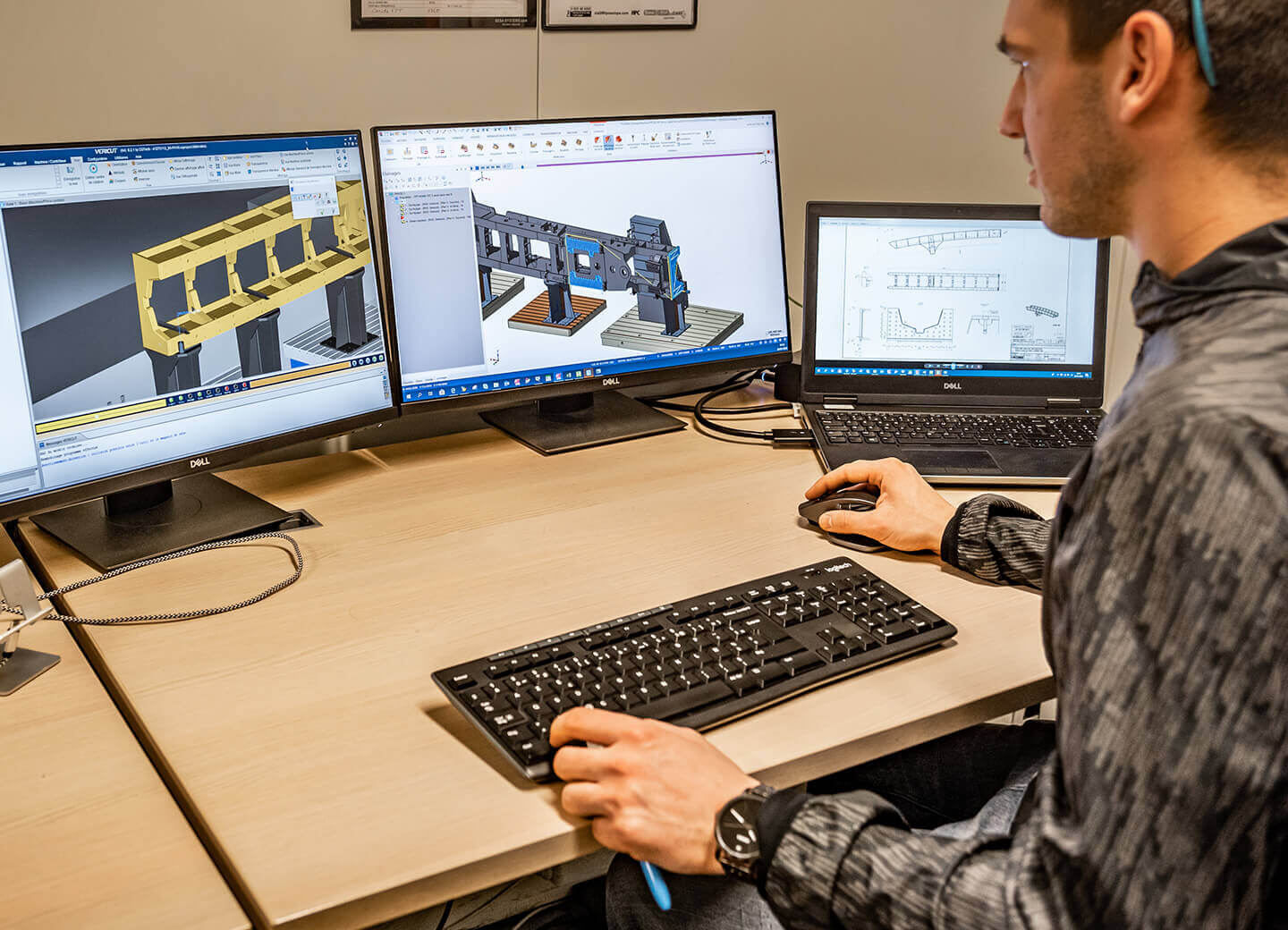

Machining of specific components

SACMI is equipped with a machining centre to ensure optimal surface finish and geometry. The functionality and the level of safety of the parts processed on site are controlled from A to Z. Machining centres are able to handle small series of parts just as well as large custom components.

Installation and pre-assembly of mechanical sub-assemblies

SACMI’s assembly workshops produce mechanical sub-assemblies from mechanically-welded and machined structures.

Station modules, station structures, motor units, voltage units, sheaves and line elements for the Group's mono-cable and multi-cable systems are pre-assembled, adjusted, wired and tested in the workshop before being shipped to the site.

This work is carried out in collaboration with POMA teams and other subsidiaries in order to maximise the added value produced in the workshop and thus reduce exposure to the constraints of external sites.

The Group’s logistics platform

The SACMI logistics department manages the flow of parts for the Group. Its main missions are the unloading and inspection of goods, inventory management, preparation of components necessary for production, loading and shipping of components to subcontractors or to construction sites.

SACMI is the main logistics platform of the POMA Group.

SACMI key figures

150

employees

100 000 sq. m

of extended site

82 km

of manual welds

6 225 sq. m

of cut sheets

60

contracts per year

The Gilly-sur-Isère production facility operated by SACMI has been designed to optimise the POMA Group’s overall production chain, in particular by internalising highly technical processes and high added-value operations that were previously subcontracted. The site is equipped with welding robots, multi-axis machining centres, complex, specific large-scale sheet metal work, etc., providing the Group with unique know-how.

With the speeding-up of flows, the POMA Group is increasingly better placed to offer a comprehensive product range on a market where time-to-market is a key value.

By refocusing a large number of production activities for its components and mechanical assemblies, POMA demonstrates its commitment to eco-responsibility; by significantly decreasing the volume of transport between operators, the Group is reducing its CO2 emissions.

CEO of SACMI

« I have worked closely with SACMI for about twelve years. I was able to closely follow the technological optimisations undertaken, and more particularly on the new Gilly-sur-Isère site. SACMI has developed unique skills in sheet-metal working for large mechanically-welded parts, in the machining of large parts as well as in the mechanical assembly of all systems. The structure’s high level of agility allows us to develop quality solutions to the challenges of producing our ropeway systems in a competitive world. »

POMA Supply Chain Manager

a flagship innovation

The 5-part sheave is a major development for the industry. Sheaves are parts at the heart of the system and are used to drive the rope. They are manufactured entirely by SACMI (assembly, welding, machining, painting and mounting of the liner) and can measure up to 6 metres in diameter.

The 5-part sheave consists of a hub and 4 quarter sheaves, which are assembled on site. This innovation optimises the possibilities of packaging, transport and handling of the equipment until it is installed on site during the construction phase.

Made in France

As part of its social commitment, SACMI regularly organises site visits to promote the “Made in France” industry and its unique know-how.

Last year, SACMI had the pleasure of welcoming:

- Students from engineering and management schools, vocational high schools,

- Professionals from the region, the sector, business associations including Talents Féminins de Savoie,

- Customers and delegations

iconic projects

Téléo

More than 8,000 passengers will board the cabins of the Téléo tricable ropeway every day. Part of the Toulouse Agglomeration’s transport network, it crosses a river and travels over a hill to link three major hubs of activity in the south of Toulouse: the University Cancer Institute, Rangueil Hospital and Paul Sabatier University.

Learn more

Miami Airport

Miami International Airport inaugurated its two APMs in 2016 and 2017. The two APM trains travel 375 m and carry up to 12,000 passengers per hour between the main terminal and terminal E.

Learn more

Ain Dubai

For the world’s largest observation wheel, commissioned for the Dubai World Expo, POMA built 48 outsized capsules, the largest and heaviest ever produced. The teams came up with evermore ingenious product development solutions and met a very high level of customer demand.

Learn moreCONTACT

396, route des Chênes – 73200 GILLY-SUR-ISERE – FRANCE

Discover our group

COMAG

COMAG is POMA Group’s expert in the installation, inspection and maintenance of ropeway transport systems.

Learn more

SIGMA

For more than 50 years, this long-standing subsidiary of POMA has specialised in the design, manufacture and final assembly of cabins for passenger transport. SIGMA’s know-how extends beyond a standard product catalogue. The company also designs and manufactures tailor-made cabins for the POMA Group’s special projects such as funiculars, APMs and observation wheel capsules.

Learn more